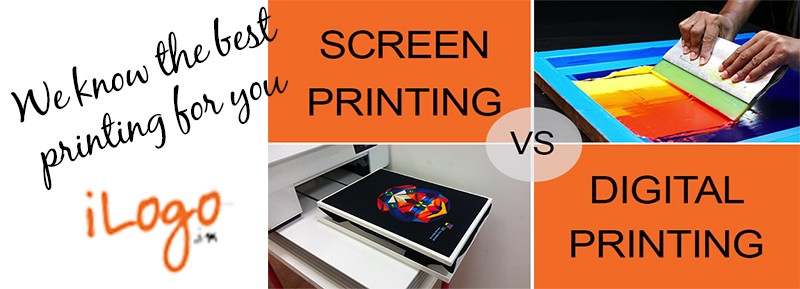

iLogo primarily offers 2 types of T-Shirt Printing & printing on Hoodies made of cotton. We provide the traditional Screen printing on majority of our products and direct to garment(DTG) on some of our products to provide you with the best finished product. For both these prinitng methods we shall explain their respective advantages and drawbacks. After reading this post, you will have a fair idea of which method of t-shirt printing to use.

Screen Printing vs Digital(Direct to Garment) Printing on Cotton T-Shirts

Screen Printing

Screen printing is the oldest and most widely used method of printing on t-shirts, hoodies and other apparel. Another name for this technique is silk screen printing. In screen printing, stencil of your design is created. The number of stencils depends on the number of colours in the design. A screen with the stencils, usually made of nylon mesh, is made to transfer the ink onto the t-shirt. The screen with the stencils is placed on the t-shirt and ink layered onto the screen. As ink is only passed through the area of the design in the stencil, the t-shirt is printed with only the design. A stencil for each colour is applied one after the other to get the final print of the design.

Direct to Garment Printing(DTG)

Direct to Garment Printing or commonly known as Digital Printing is a relatively new technique. In DTG, the artwork is processed on a computer and then the T-Shirt is printed directly with the help of DTG Printer. Direct to Garment(DTG) Printing is not the same as Heat transfer as in DTG, the ink is layered directly onto the fabric of the t-shirt while in Heat transfer, the design is printed onto a paper which is then transfered to the t-shirt by applying high pressure and temperature. As DTG is printed directly on the fabric vs onto a paper and then heat transferring, the quality of DTG is much superior in quality.

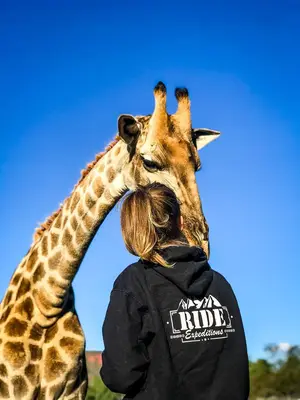

Screen printing is best suitable for designs which have a larger run and require vibrant prints on dark colours. As screen printing is processed manually, they can be printed on unique locations like the sleeve, collar and edges of the seams. The minimum quantity of screen printed products exist because of the extra labour, material and processes associated with the printing technique. Screen printing can also not be used to print photographs and similar designs as they cannot be seperated into different unique colours.

Direct to Garment Printing is best suitable for designs which have a high degree of details and, orders of a smaller quantity. As Digital print is not printed with stencils but the image printed directly onto the fabric, it allows for photgraphic images to be printed with much more details than the traditional screen printing. As the ink is layered thinly on the fabric to enable the finer detailing, they are best suited for lighter coloured t-shirts. As they are printed using a DTG printer and there is no set up involving screens, even a single t-shirt can be printed.

Screen Printing has the following advantages:

- Screen printing method is ideal for high quality printing of t-shirt designs, because it guarantees the exact replication, consistent quality and durability

- It is cost effective in volume.

- It is also scalable as the mesh screen and templates can be reused several time.

Screen Printing however has it's disadvantages:

- Screen printing is not feasible for single t-shirt orders. iLogo has a minimum requirement of 6 t-shirts for screen printing.

- Screen printing is also not suitable for complex designs with multi-colours and gradients.

- Screen printing takes longer for set up as screens and stencils need to be made.

- As each colour needs to be seperated as unique to be used through stencil, colour accuracy might become an issue

Direct to Garment(DTG) Printing

Next on the line is the Direct to Garment(DTG) method. This is a relatively new method of t-shirt printing and was introduced only in 2005. It involves printing directly on the t-shirt. It is printed using a DTG Printer. This works exactly the same way printing is done by an inkjet printer on paper.

Being able to print directly on the t-shirt with a machine has the following advantages:

- Detailed Printing - As this prints directly on the t-shirt, complex designs and colours can be printed.

- One offs - As there is no set up required, it is ideally suitable for one off prints.

- Quick delivery - As it can be printed directly on the t-shirt, this can be printed at short notice.

Considering DTG printing is an emerging technology, it has some inherent disadvantages:

- Price - The DTG printer and the ink used is relatively expensive. And as the cost increases linearly with volume, it is not cost effective for larger runs.

- Consistency - The prints are not consistent and depends a lot on variables like temperature, material of the t-shirt and pretreatment liquid.

- Placement - As the print is done with machine on a flat bed, the print cannot be done at unconventional design positions

- Colour - Colour matching of the print cannot be done, as the software and machine interprets the colours by converting RGB to CMYK.

- Quality - The print quality is not as good as Screen Prints. The print may fade after a few washes

At iLogo, we are continually working on getting the latest available printing techniques. We offer the best industry practices in T-Shirt & Custom Hoodies printing. We strive to continuosly improve and ensure that both forms of printing are to the best standards of quality to ensure that you receive a superior custom product. Designs for both forms of printing are reviewed by our expert artists to ensure that you receive the best finished custom T-Shirt.