Screen Printing

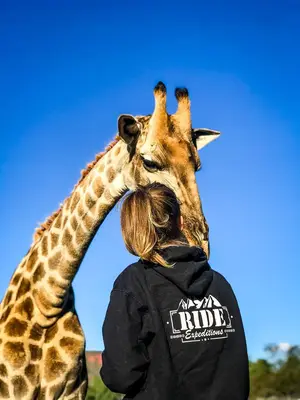

Screen printing is still the most proffessional way of printing on t-shirts. Another name for this technique is silk screen printing. If you have a t-shirt or polo shirt with a soft print with consistent colours, this is most probably the type of printing. These prints remain vibrant, bright and last for long. You can count on screen print for most of your t-shirt printing needs including polo shirts, hoodies and other apparel. However, it may not be the best option for all occasions.

Screen printing requires you to create a stencil or template of the design. This is held in place with the help of a screen which is, usually, made of nylon mesh. The screen is the placed in position on top of the t-shirt to be printed. Ink is then flooded onto the screen and spread to ensure it fully spread on the screen. The ink passes through the wire mesh and the stencil of the design to print onto the t-shirt. Excess ink on the screen is wiped away. The screen is then removed and the t-shirt cured, cured and ready!

Screen Printing has the following advantages:

- Screen printing method is ideal for high quality printing of t-shirt designs, because it guarantees the exact replication, consistent quality and durability

- It is cost effective in volume.

- It is also scalable as the mesh screen and templates can be reused several time.

Screen Printing however has it's disadvantages:

- Screen printing is not feasible for single t-shirt orders. iLogo has a minimum requirement of 6 t-shirts for screen printing.

- Screen printing is also not suitable for complex designs with multi-colours and gradients.

- Screen printing takes longer for set up as screens and stencils need to be made.

- As each colour needs to be seperated as unique to be used through stencil, colour accuracy might become an issue